You know that ball valves are very important parts of piping systems if you are an oil or gas engineer. Ball valves are use for many different purposes in the oil and gas industry. In upstream applications, they control the flow of oil. Midstream companies protect equipment by controlling the flow of gas and oil. Downstream, they are using to refine crude oil.

Engineers must be familiar with the various types of valves, or at least the most common ones, due to their widespread use in the industry.

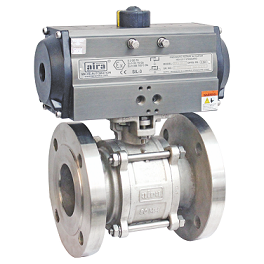

Ball Valve Components

A ball valve consists of the body, the ball itself, the steam, and the seats.

A ball valve may be soft-seated or metal-seated. Depending on how many valve ports and seats there are, it can be bidirectional, multidirectional, or unidirectional. This applies to multiport plug valves as well.

Advantages and applications of ball valves

- Ball Valves can use as on/off stop valves with bubble-tight shut-off for different fluid services.

- In addition to hydrocarbon systems, they can also use in air, gaseous, and vapor systems.

- Instrument tubing can use to connect them.

- High-temperature and high-pressure applications benefit from metal-seated ball valves.

- These valves are cost-effective as well as easy to operate.

- It’s easy to find the right ball valve for your needs with a variety of types and configurations.

- Compared to gate valves of the same rating and size, ball valves are more compact and lightweight.

- They can be opened and closed quickly, with bubble-tight sealing, even in high-pressure situations.

1. Three-Way Ball Valve

The ports of a three-way ball valve can be set in one of three ways, depending on the situation:

The one inlet, two outlets;

one inlet, one outlet, and a diverted flow; or

The one inlet, one outlet, and no diverted flow.

There are three types of ball valves: full port type, reduced port type, and Venturi port type.

A full port type has an internal diameter that is equal to the internal diameter of the pipe. A pig can be inserted into this type of port. Reduced and Venturi port types usually have ports that are smaller than the size of the line.

The spherical ball inside the valve can be either free-floating or fixed. These types are referred to as floating types and fixe types, respectively. Fixed types are sometimes refer to as mounted ball valves.

2. Floating Ball Valve

The ball is held in place by two elastomeric seats in a floating ball valve. Between these seats, the ball can “float” inside the valve’s body.

A slot in the top of the ball connects the valve stem to the ball. The ball can rotate one-quarter turn or 90 degrees.

A limited amount of lateral movement is allow by the valve shaft, which is generate by the upstream pressure against the ball. Despite its small size, this lateral movement drops a load on the ball that presses the ball against the downstream seat. It improves tightness and helps prevent leaks.

A bidirectional shutoff is possible with this type of ball valve. If the upstream pressure is high, a floating ball valve can be difficult to operate. Instead, a mounted ball valve is use.

3. Mounted Ball Valve

This mounted ball valve offers a solution to the problem of excessive pressure placed on a floating ball valve.

The body of a mounted American ball valve has a short shaft, called a trunnion. Using this design, the ball and steam work together as a single unit. The ball is support by two floating or spring-loaded seats.

This type of ball valve requires less torque to operate. In turn, this reduces the size of the actuator as well as the cost of the valve. The cost difference increases as valve size and pressure class increase.

4. Split-Body Ball Valve

Split-body ball valves have their bodies divided into halves or thirds. Bolting holds the ball, stem, seat rings, and other internal mechanisms together inside the body.

Aira euro automation is one of the leading Ball Valve Manufacturer in Yemen. Aira has a wide range of industrial valves.