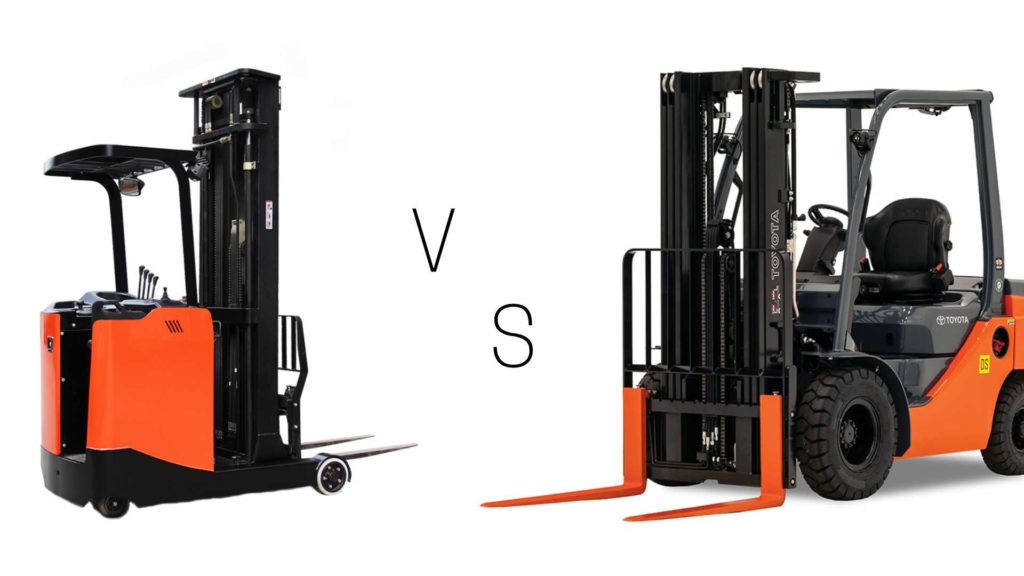

Electric Forklift Vs. IC Forklift:

Electric forklifts are powered by a battery that serves as a counterweight to keep the equipment and power source stable while in use. Additionally, the battery’s quiet operation, low emissions, and rechargeability contribute to environmental protection.

Internal combustion engines (IC) in forklifts The internal combustion engine (IC) in forklifts functions similarly to the gasoline-powered engine in your car. This fuel is typically gasoline, diesel, LPG, or compressed natural gas for forklifts for rent or sale.

What applications work best for electric and IC forklifts?

Electric-powered forklifts and IC forklifts can be used in certain industries that do not have any special requirements.

Stacking loads that weigh more than 5 tons is required in some industries.IC forklift is needed.

Most of the time, some industries need to work outside on bad floors;I require an IC forklift.

A clean environment is necessary for some industries, like the food or medical industries; Typically, an electric forklift is required.

Electric forklifts are required by some industries that require a large number of forklifts and want to keep usage costs low.

Electrically operated elevators may also be required in other sectors due to concerns about emissions, employee safety, or infrastructure design. These lifts include Food and drug processors – cold storage – minimal cold storage; grocery and retail pharmaceuticals; medical equipment and pharmaceuticals; and beverage processors – cold storage – minimal cold storage. In addition, the use of electricity was a common trend in warehouse settings, particularly those with tall shelves and extremely narrow lanes.

The costs of purchasing an electric forklift

An electric forklift is more expensive to buy than an electric forklift. which is because you pay for the forklift in its entirety. Due to the battery, the commercial forklift battery in the Toyota three-wheel electric forklift will initially be charged. However, compared to IC forklifts, the general holding fee is lower. Eyewash stations, a battery-operated guard, and a separate charging location with adequate airflow all require payment.

Additionally, hiring an electrician to connect and unload the charger may be necessary. In addition, the charger is compatible with the electrical device in question.3 A brand-new HV line is required. He claims that IC forklifts have lower general fees of ownership than electric forklifts do.

However, First Energy claims that the cost of operating an electric forklift truck is 75% less than the cost of operating an electric forklift truck in everyday use. Approximately one to two years, or the equivalent, and when the forklift’s lifespan reaches at least ten years, the electric forklift becomes more affordable in the future.

Maintenance:

Electric forklifts have fewer moving parts than IC forklifts, which is one of their main advantages over IC forklifts.

Since there are fewer moving parts, less maintenance is always required.

Then, this means less downtime and lower costs.

In contrast, IC forklifts require routine daily upkeep, which includes, but is not limited to:

- Air/fuel mixture adjustment via the overhead cooling system,

- oil replacement,

- engine modifications

If the cost of maintaining electric forklifts is about. 20 per hour, maintenance costs of IC forklifts. 00 at least.

- It means a lot to me. When using electricity, this amounts to a reduction in overall maintenance costs of approximately 40%.

- In comparison to electric forklifts, IC forklifts suffer from some of the disadvantages of cold weather.

- Starting them in cold weather can be challenging due to their increased number of mechanical parts.

- However, these restrictions are not present with electric forklifts.

They are well-liked in food processing plants and cold storage facilities.